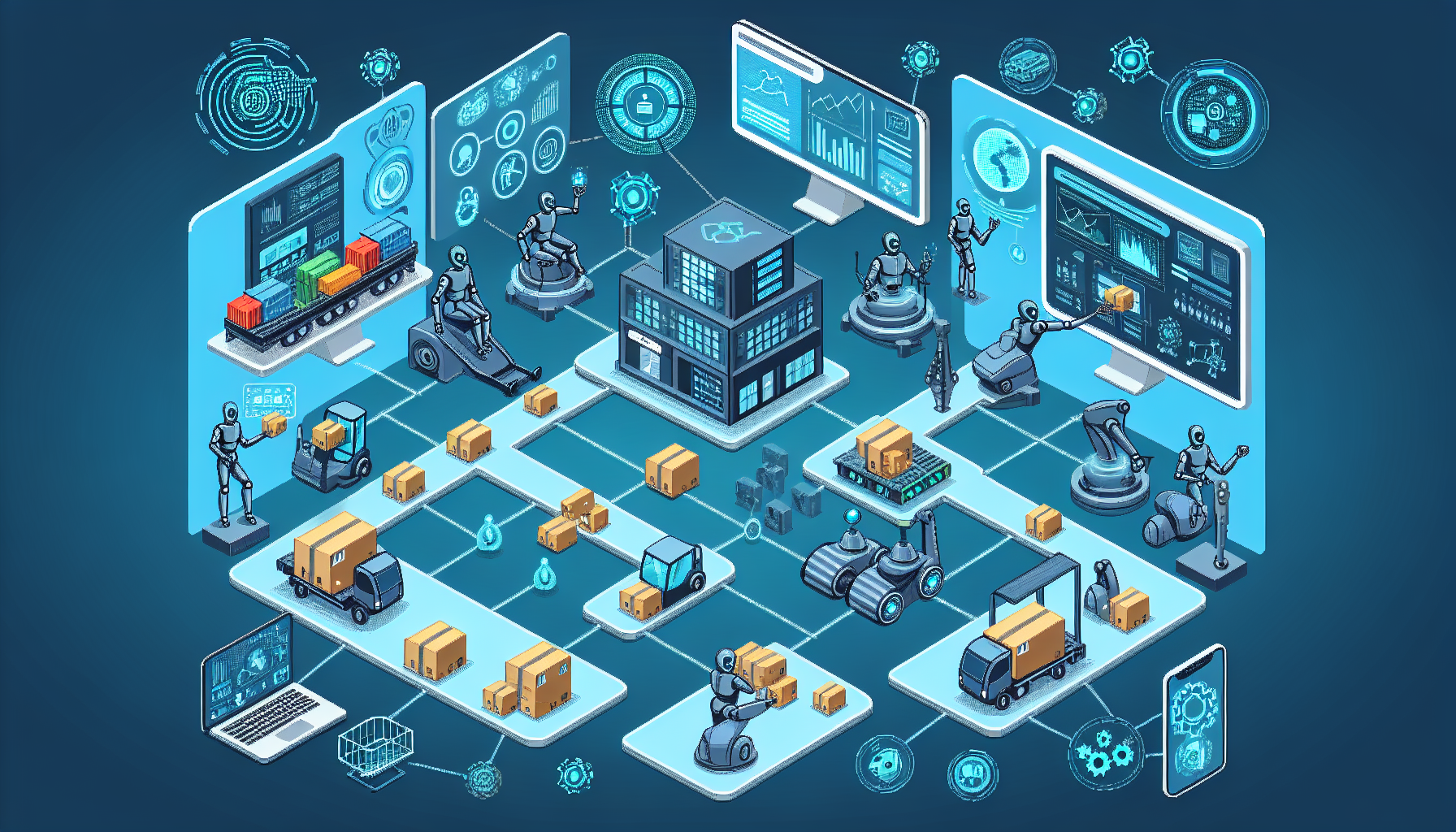

Optimizing Supply Chain Operations with AI Automation

Understanding AI Automation in Supply Chain

Artificial Intelligence (AI) has revolutionized various sectors, and supply chain management is no exception. AI automation encompasses using software and algorithms to perform tasks that traditionally required human intervention. The supply chain involves a myriad of operations, from procurement and logistics to inventory management and demand forecasting. Employing AI in these areas promises efficiency, accuracy, and cost reduction.

Benefits of AI in Supply Chain Management

-

Enhanced Forecasting Accuracy

AI algorithms can analyze vast amounts of historical data to predict future demand with remarkable accuracy. This predictive capability allows companies to align their inventory levels with actual market conditions, reducing overstock and stockouts. -

Increased Operational Efficiency

By automating routine tasks such as order processing, invoice management, and inventory tracking, AI helps streamline operations. This allows human resources to focus on strategic decision-making rather than mundane tasks. -

Supply Chain Visibility

AI-powered tools provide real-time visibility into supply chain operations. This transparency is crucial for monitoring performance, identifying bottlenecks, and ensuring that all stakeholders are informed, leading to more agile decision-making. -

Risk Management

With AI’s ability to analyze external factors—such as geopolitical events, environmental changes, and market trends—companies can better anticipate disruptions and adjust their strategies accordingly. -

Cost Reduction

By optimizing routes, automating warehouses, and managing supplier relationships effectively, AI helps enterprises significantly cut logistics and operational costs.

Key Areas Where AI Automation Thrives

-

Inventory Management

AI systems can autonomously manage stock levels, analyze usage patterns, and forecast demand fluctuations, leading to optimized inventory holding costs and improved order fulfillment efficiency. -

Transportation and Logistics

Automated route optimization and predictive maintenance for vehicles can vastly improve delivery times and reduce fuel consumption. AI allows for real-time tracking of shipments, predicting delays, and suggesting alternative routes. -

Supplier Relationship Management

AI can analyze supplier performance metrics, facilitated by natural language processing to evaluate communication effectiveness. By gaining insights into supplier reliability, businesses can strengthen their supply chain partnerships. -

Warehouse Automation

Robotics powered by AI enhance warehouse operations through automated picking and sorting systems that increase the speed of order fulfillment. AI-driven inventory systems minimize human error and streamline operations. -

Demand Planning

Advanced machine learning models dig deep into data patterns to derive actionable insights concerning consumer behavior and trends, enabling better planning and alignment of resources.

Implementing AI Automation in Supply Chain

-

Assess Current Operations

Before implementation, companies must summarize existing processes to identify gaps and inefficiencies. A SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) can serve as a useful tool in this assessment. -

Set Clear Objectives

Establish measurable goals for AI projects, such as reducing operational costs by a certain percentage or improving delivery accuracy. Clear objectives guide the implementation process and help in evaluating success. -

Choose the Right Technology

Select AI solutions that meet specific organizational needs. Whether opting for proprietary software or cloud-based applications, it’s vital to ensure compatibility with existing systems. -

Pilot Projects

Initiate AI projects on a small scale to monitor performance without fully committing. This pilot phase helps businesses iterate based on initial results and stakeholder feedback. -

Train Staff

Employee training is fundamental to successful AI integration. Workers should be adept at using new technologies and understanding AI’s capabilities, which fosters wider acceptance and enhances productivity. -

Monitor and Adjust

Regularly evaluate the performance of AI systems. Using KPIs (Key Performance Indicators), companies can ensure that the technology meets set objectives. Be prepared to revisit strategies and improve processes.

Challenges of Implementing AI in Supply Chains

-

Data Quality and Integration

Successful AI implementation is heavily reliant on high-quality data. Companies often face challenges in integrating different data sources into a cohesive system. -

Resistance to Change

Employees may resist transitioning to AI-driven processes due to fear of job displacement or both, being accustomed to traditional workflows. Effective change management and communication are crucial. -

Cost of Implementation

Initial setup costs can be significant. Companies must weigh the long-term benefits against upfront investments, justifying ROI through improved efficiencies in supply chain processes. -

Cybersecurity Risks

As supply chains become increasingly digital, the risk of cyber-attacks escalates. Businesses must implement robust cybersecurity measures to safeguard sensitive data.

The Future of Supply Chain AI Automation

The potential for AI automation in supply chains continues to grow. Innovations in IoT (Internet of Things), Blockchain, and Machine Learning will further enhance real-time collaboration, transparency, and risk management.

-

Predictive Analytics

Future AI models will leverage additional data types, including social media sentiment and economic indicators, to forecast demand and manage supply chain dynamics even more precisely. -

Smart Contracts

Blockchain technology will provide increased security and automate transactions between supply chain partners, facilitating faster payments and reducing disputes. -

Hyperautomation

The convergence of AI, ML, RPA (Robotic Process Automation), and IoT will foster hyperautomation in supply chains, allowing for autonomous decision-making processes that vastly accelerate operations. -

Sustainability Initiatives

AI will play a pivotal role in optimizing sustainability efforts within supply chains, helping companies track carbon footprints, optimize resources, and adhere to regulations more effectively. -

Customization and Personalization

As customer expectations evolve, AI will assist businesses in achieving greater customization and personalization within their supply chains, improving customer satisfaction and loyalty.

By leveraging AI automation, businesses not only optimize their supply chain operations but also create a robust framework for future growth and resilience in an ever-changing marketplace.